Natural Cut Stone

Delivering some of North America’s most spectacular natural stone from the Earth’s surface to you.

DISCOVER KAFKA’S PREMIUM NATURAL CUT STONE PRODUCTS

Composed of spectacular granite, marble, and quartzite, our premium natural cut stone products are ideal for wherever you want to make a show-stopping first impression. Natural cut stone offers color that never fades or weathers over time, lasting for a lifetime of enjoyment. Choose only the best materials for your project — start browsing Kafka Granite’s Natural Cut Stone products today.

Looking for a Custom Stone Solution?

Kafka Granite takes pride in creating customized solutions to address customer needs. Whether you need a fireplace mantel or hearth stone of a particular size or thickness, a specific height of thin stone veneer, or a custom blend of stone to create the perfect exterior facade, Kafka can deliver the perfect result. All of Kafka’s natural cut stone products are produced as they are ordered, allowing for a multitude of customization options.

Contact UsFeatured Projects

Frequently Asked Questions

Manufactured or artificial stone is man-made and typically crafted from concrete and other materials. This type of product can be molded to resemble natural stone, but is far from the real thing. Kafka’s natural cut stone products consist entirely of quarried rock, creating a beautiful, organic quality that can’t be replicated. Each piece of natural stone is completely unique, giving it truly exceptional character. Additionally, natural cut stone maintains its color and integrity as it weathers, while man-made concrete materials contain oxide colors and other chemicals that will fade over time.

Typical outcropping stone is rough on all sides, which requires extra time and effort during installation. When developing Kafka Granite’s Natural Stone Hardscapes, we wanted to create a natural stone product line that performs better and installs more easily. Our cut drywall is sawn on the top and bottom, streamlining the installation process. While dry stacked walls still need to be professionally installed, this process will proceed more quickly and smoothly than it would with traditional outcropping stone.

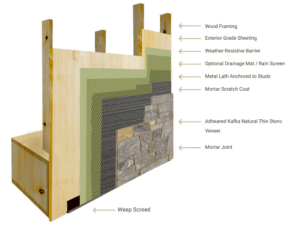

To ensure the integrity and longevity of a project, we recommend having a professional mason install our natural thin stone veneer. If this specialty building product is being utilized in an exterior project, the area that will be in contact with the product must first be waterproofed to industry standards. Next, any chemical film on the wall should be removed. Additional surface preparation may be necessary, depending on the type of material. Some surfaces will need a non-corrosive wire lath and a setting mix before the material is applied. To set the product, begin with any corner pieces and alternate long and short ends while stacking them on top of each other. Type N or S mortar is suitable for most projects, possibly with the addition of a bonding admixture. Once the corners are complete, the rest of the pattern can be filled in by pressing each stone against the scratch coat wall. Mortar should be allowed to ooze and create grout joints around the edge of each stone.

All of Kafka’s hardscapes are sawn to height, which effectively eliminates the need for shimming and re-leveling during installation. This provides a significant advantage over other natural stone products that are uneven. The end result is a quicker setup process and more efficient installation, with the potential for a lower final project cost.

Depending on the type of thin stone veneer you’ve chosen for your project, type N or type S mortar will fit your needs. Type N is a reliable, general-purpose mix with a medium compressive strength, while type S provides a high-tensile bond strength and a high compressive strength. Type N is well-suited for exterior and above-grade projects that are exposed to severe weather and high temperatures, as well as interior installations. Soft stone masonry, above-grade walls, and chimneys are just a few examples of projects that would most likely require type N. With a minimum compressive strength of 1,800 psi, type S can be considered a more “heavy-duty” mortar and is ideal for applications like exterior masonry and other projects that need to withstand forceful winds and soil pressure.