Thin Stone Veneer

Unique and Classic Thin Stone Veneer

Kafka Granite’s natural Thin Stone Veneer offers a unique, high-end alternative to common products on the market today. With a broad range of cuts and colors, this specially-made thin cut stone veneer adds show-stopping, distinctive character to any project’s interior or exterior—especially when paired with our other cut stone products.

Derived from our various quarries throughout North America, our line of Thin Stone Veneer is comprised of stunning natural stone that can be used for nearly any application, from building facades to interior features. With a vast range of cuts and colors, many of our Thin Stone Veneer products have never been seen before, yet still feel familiar enough to be embraced by architects, masons, and property owners alike. Whether you’re looking for thin granite veneer, stunning marble or quartz veneer, or shopping by cut and color, Kafka has what you need to take your project to the next level.

Chateau Granite

Castle

Chateau Granite

Dimensional

Chateau Granite

Drystack

Chateau Granite

Mosaic

Ebony Glitter

Castle

Ebony Glitter

Dimensional

Ebony Glitter

Drystack

Ebony Glitter

Mosaic

Ebony Glitter

Ledgestone

Galaxy Glitter

Dimensional

Galaxy Glitter

Drystack

Galaxy Glitter

Ledgestone

Galaxy Glitter

Mosaic

Galaxy Glitter

Castle

Gun Metal Marble

Castle

Gun Metal Marble

Rustic

Gun Metal Marble

Mosaic

Gun Metal Marble

Ledgestone

Gun Metal Marble

Drystack

Gun Metal Marble

Dimensional

Harvest Gold Sandstone

Castle

Harvest Gold Sandstone

Dimensional

Harvest Gold Sandstone

Drystack

Harvest Gold Sandstone

Mosaic

Harvest Gold Sandstone

Ledgestone

Imperial Gray Granite

Castle

Imperial Gray Granite

Dimensional

Imperial Gray Granite

Drystack

Imperial Gray Granite

Ledgestone

Imperial Gray Granite

Mosaic

Jade Granite

Mosaic

Misty Gray Marble

Castle

Misty Gray Marble

Dimensional

Misty Gray Marble

Mosaic

Misty Gray Marble

Ledgestone

Misty Gray Marble

Drystack

Patina Granite

Rustic

Sedona Glitter

Castle

Sedona Glitter

Dimensional

Sedona Glitter

Mosaic

Sedona Glitter

Drystack

Starlight Black Granite

Dimensional

Starlight Black Granite

Drystack

Starlight Black Granite

Ledgestone

Starlight Black Granite

Castle

Starlight Black Granite

Mosaic

Wisconsin Granite Fieldstone

Round Side OutADVANTAGES

Kafka’s natural Thin Stone Veneer has a nominal thickness of ¾” to 1½”, resulting in a natural stone product 15lbs or less per square foot. The lightweight pieces help reduce production, shipping, and construction costs. In addition, our Thin Stone Veneer can be installed without footings or ledges, and adheres to concrete, plywood, paneling, drywall, and even metal, making it a great embellishment indoors—like on kitchen islands and bars, fireplaces and more—or across exterior cladding.

Because Kafka only produces authentic stone product, the natural colors of our granite, quartzite, and marble exist throughout the entire stone. Kafka’s natural Thin Stone Veneer wears and weathers naturally, maintaining its integrity through the life of your project.

Kafka also offers another big advantage – we have the ability to source your entire project from the same quarry, ensuring that any complementary natural stone products are perfectly cohesive.

Featured Projects

Frequently Asked Questions

Thin stone veneer is the perfect option for giving an interior or exterior project the beautiful look of natural stone. Due to its light weight, this specialty building material doesn’t require the use of footings or support ledges for installation. It can also be adhered to a variety of surfaces with the proper surface preparation. These qualities make the versatile material ideal for many kinds of non-structural projects, like fireplaces, pillars, chimney facades, and decorative walls. And because Kafka Granite’s high-quality thin stone veneer consists entirely of quarried stone, the material will retain its integrity when exposed to the elements—meaning that it’s also a suitable choice for exterior projects like building facades.

Natural thin stone veneer and natural full stone veneer are made from the same high-quality natural stone, but an additional process makes thin stone veneer thinner. The result? A versatile masonry product with the beauty of natural stone but a fraction of the weight of full veneer building stone. In fact, thin stone veneer can weigh up to 75 percent less than full veneer! This relatively light weight reduces shipping costs drastically. The two products also differ on installation costs: full veneer may require more shaping on the jobsite, and therefore will take more time, effort, and funds to install than thin stone veneer. Ultimately, natural thin stone veneer allows designers, architects, and even homeowners to incorporate the rugged beauty of natural stone into non-structural projects while minimizing the costs associated with full veneer.

Depending on the type of thin stone veneer you’ve chosen for your project, type N or type S mortar will fit your needs. Type N is a reliable, general-purpose mix with a medium compressive strength, while type S provides a high-tensile bond strength and a high compressive strength. Type N is well-suited for exterior and above-grade projects that are exposed to severe weather and high temperatures, as well as interior installations. Soft stone masonry, above-grade walls, and chimneys are just a few examples of projects that would most likely require type N. With a minimum compressive strength of 1,800 psi, type S can be considered a more “heavy-duty” mortar and is ideal for applications like exterior masonry and other projects that need to withstand forceful winds and soil pressure.

Manufactured or artificial stone is man-made and typically crafted from concrete and other materials. This type of product can be molded to resemble natural stone, but is far from the real thing. Kafka’s thin stone veneer products consist entirely of quarried rock, creating a beautiful, organic quality that can’t be replicated. Each piece of natural stone is completely unique, giving it truly exceptional character. Additionally, our thin stone veneer products maintain their color and integrity as they weather, while man-made concrete materials contain oxide colors and other chemicals that will fade over time.

Our natural thin stone veneer has a nominal thickness of ¾” to 1½”, allowing this masonry product to meet the standard of weighing less than 15 lbs per square foot. As further evidence that our line of natural stone veneers is authentic and up to our standards, you’ll find that the natural colors of our various stone options run through the entire product, allowing it to weather naturally while maintaining integrity as a fundamental element of your project.

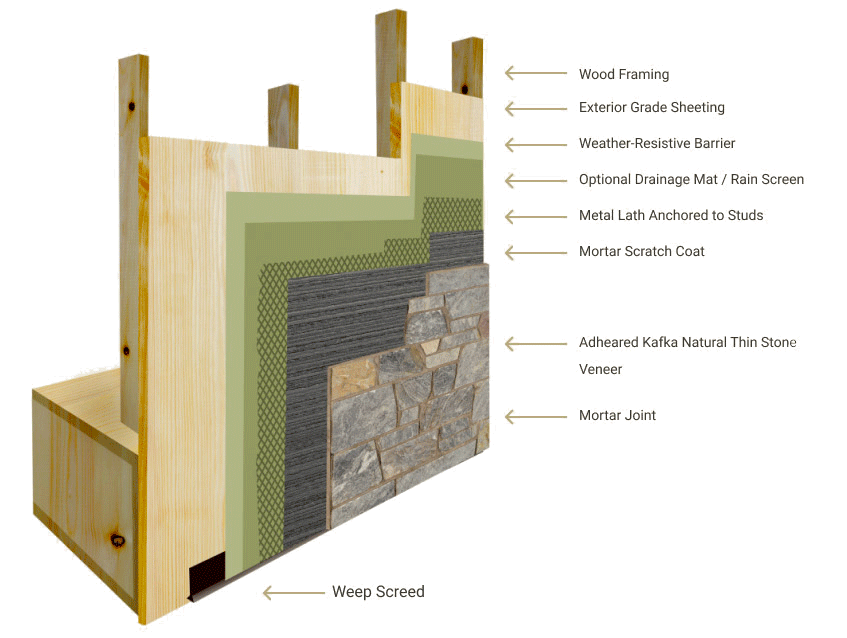

To ensure the integrity and longevity of a project, we recommend that a professional mason install our natural thin stone veneer. If this specialty building product is being utilized in an exterior project, the area that will be in contact with the product must first be waterproofed to industry standards. Next, any chemical film on the wall should be removed. Additional surface preparation may be necessary, depending on the type of material. Some surfaces will need a non-corrosive wire lath and a setting mix before the material is applied. To set the product, begin with any corner pieces and alternate long and short ends while stacking them on top of each other. Type N or S mortar is suitable for most projects, possibly with the addition of a bonding admixture. Once the corners are complete, the rest of the pattern can be filled in by pressing each stone against the scratch coat wall. Mortar should be allowed to ooze and create grout joints around the edge of each stone.

Installation

Kafka Natural Thin Stone Veneer and Natural Stone Accents are fabricated to offer the original beauty that only natural stone can provide, but is designed for a lightweight, non-structural installation.

For additional information about installation, please contact us.