Every year, Kafka Granite helps hundreds of clients create stunning outdoor spaces. From ballparks to city parks, we want everyone to be able to enjoy the areas that we assist in creating—that’s why offering commercial wheelchair accessible materials is so important to us.

Providing accessible pathways is a federally mandated priority for all designers and architects. In 2010, the Department of Justice published revised regulations for Titles II and III of the Americans with Disabilities Act (ADA) of 1990. These regulations set minimum requirements for newly designed and constructed state and local government facilities, public accommodations, and commercial facilities. Below, we’ve broken down the logistics of creating accessible pathways.

Firmness, Stability, and Slip Resistance In Wheelchair Accessible Walkways

Under the 2010 ADA regulations, accessible outdoor flooring and ground surfaces must be stable, firm, and slip-resistant. The ADA regulations define a stable surface as something that resists movement, while a firm surface is something that resists deformation by applied force, and an accessible surface is something that remains unchanged by external forces, objects or materials.

Exceptions to the ADA Regulations

There are a few exceptions to the 2010 regulations. The following areas are not required to meet ADA standards of being stable, firm, and slip-resistant:

- Animal Containment Areas

- Areas for Sports Activities

- This does not imply that sports arenas and sport viewing areas do not need to meet the ADA standards—this exception only refers to the physical area when the sport shall be played. A good example here would be a football stadium. The stadium itself must have accessible entrances and accommodations that meet ADA regulations, but the actual playing field does not need to exhibit these traits.

Wheelchair Accessible Pathway Specifications

To be classified as an accessible route, pathways must meet or contain one or more of the following requirements and attributes:

- A running slope no steeper than 1:20

- The cross slope of walking surfaces cannot be steeper than 1:48

- Changes in level with a maximum of ¼ inch are permitted to be vertical

- Changes in level between ¼ inch and ½ inch need to be beveled with a slope not steeper than 1:20

- Changes in level greater than ½ inch must be ramped

- Doorways that provide a clear width of 32 inches

- Curb ramps excluding flared sides

- Elevators with accessible features

- Platform lifts

The width of your pathway must be at least 36 inches; you are allowed to narrow your walkways to 32 inches wide for a length of 24 inches every 48 inches. Let’s look at a practical example. If you wished to have planters that protrude onto your pathway, those planters can only stick out 4 inches onto the pathway, and they must be spaced 48 inches apart. This width requirement helps to ensure wheelchair accessibility and keeps your pathways compliant.

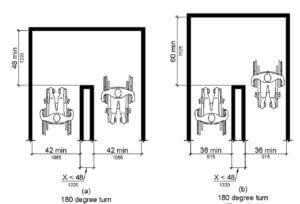

Two additional features your accessible pathways must contain are passing space and turning space. An accessible route with a width less than 60 inches must provide passing spaces at intervals of 200 feet. Additionally, if your pathway contains any 180º turns, your turning space must be either 48 inches, or 60 inches, depending on the width of the pathway.

Planning out wheelchair accessible routes may require a more comprehensive look at your entire project. Here are some questions that you should ask yourself after you have finished designing your structure’s new accessible pathways:

- Is there a route available that does not include stairs?

- Is that route firm and slip resistant?

- Are your pathways at least 36 inches wide?

- Can all objects that protrude onto the pathway be detected from the vantage point of someone in a wheelchair or by someone with a visual impairment?

- If your walkway is lined by curbs or raised edging does that edging drop off at entrances and exits on the path?

- If ramps are present, are their slopes less than 1:20?

- Do ramps that are longer than 6 feet have railings on both sides?

- Are any railings present sturdy and between 34-68 inches high?

- Are all public spaces on an accessible route?

- Is there a 5-foot circle or a T-shaped space for a person using a wheelchair to reverse direction?

- Are all signs mounted with their centerline 60 inches from the floor?

- If there are restrooms available on the property, is at least one restroom fully accessible?

These and similar questions will help you examine the design of your accessible pathways from a variety of angles, and they’re critical before entering the building and pathway installation stage. If you discover an issue with your wheelchair accessible routes, you’ll be able to adjust your designs to ensure that your new pathways do, in fact, meet ADA regulations.

Kafka Granite Commercial Wheelchair Accessibility Materials

Common materials for wheelchair accessibility include asphalt and concrete. These materials result in smooth, accessible pathways, but they don’t offer the most natural of aesthetics. In fact, they can often stand out from their surroundings, disrupting the overall look of an outdoor space. So, what can designers and architects do when a natural look and feel is desired but wheelchair accessibility is required? Kafka Granite has a solution—our Stabilized Pathway Mix.

Decomposed Granite as an Asphalt Alternative

Stabilized decomposed granite pathways are an excellent alternative to asphalt and concrete pathways. Not only does decomposed granite traditionally cost less than asphalt and concrete over the span of its lifetime due to its limited maintenance, but our Stabilized Pathway Mix made with Organic-Lock has been tested for ADA accessibility and has met the maneuverability performance requirements of ASTM F 1951-09b.

Stabilized decomposed granite pathways are an excellent alternative to asphalt and concrete pathways. Not only does decomposed granite traditionally cost less than asphalt and concrete over the span of its lifetime due to its limited maintenance, but our Stabilized Pathway Mix made with Organic-Lock has been tested for ADA accessibility and has met the maneuverability performance requirements of ASTM F 1951-09b.

Kafka Granite is an industry leader in natural pathway products. Our Stabilized Pathway Mix is comprised of decomposed granite or crushed stone screenings crushed to spec and blended with a stabilizing binder called Organic-Lock. This combination binds and locks the pathway mix to provide a durable, permeable, and natural aggregate surface. Kafka Granite’s Stabilized Pathway Mix resists the erosive effects of weather and traffic better than traditional gravels or limestone screenings. When this mix is installed correctly, it can qualify as an ADA accessible pathway surface.

With a natural look that is significantly less obtrusive than concrete or asphalt, our Stabilized Pathway Mix blends in well in natural settings, making it an attractive option for use in botanical gardens, green roofs, nature paths, greenways, golf course cart paths, trails, or any environment where a more organic feel is desired.

Kafka Granite offers Stabilized Pathway Mix in over 50 colors. The pathways are easy to install, require little maintenance, and offer various edging options such as pavers, concrete, sod, natural grasses, or wood chips. If you’ve been tasked with installing wheelchair accessible pathways in an outdoor space, you may have just found your ideal pathway material.

Stabilized Pathway Installation Instructions

To create reliable, accessible pathways, it’s essential that your pathway mix be installed correctly. Here is a helpful breakdown of the necessary installation instructions.

- Prepare the subgrade and spread the base course material to the approved depth and compact with a 1-3 ton roller. Allow for 20-25% compaction. A crushed, angular road base such as a ¾” minus is an optimal base material. For pedestrian applications, base should be 4-6 inches compacted; for vehicular applications, base should be 8-12 inches compacted. To assist in the bonding of materials, pre-soak the base course before placement of the stabilized pathway mix.

- Pre-hydrate the stabilized pathway mix at the job site—this activates the stabilizing binder. Turn the pathway mix until a moisture level of 10-12% has been reached. You should be able to easily pack a “snowball” with the product, without water oozing out.

- The stabilized pathway mix must be spread and compacted. Screed if possible. For large installations, using a paving machine for this step is highly recommended to ensure the material is evenly spread at the specified depth.

- Compact the stabilized pathway mix using a 1-3 ton double drum or single static drum roller. Do not use a vibratory plate compactor or vibratory setting for this step. When no further visible roller marks can be seen on the surface, compaction of the pathway is complete.

- Ensure the pathway is level. The pathway should rest true to elevation and shouldn’t vary more than ¼” at any spot when tested with a straightedge. The surfaces should be crowned at a minimum of 2% and be flush with adjacent materials or edges. The pathway should also be sloped at least 1% to drain away from structures.

- After the pathway has been compacted and leveled, apply a light spray to the surface to give it a clean appearance. Once the water begins to run off the surface, stop spraying the pathway.

- Once the surface of the pathway has visually dried, light pedestrian traffic can take place on the new surface. However, the stabilized DG pathway should fully cure before heavy foot traffic or vehiclar traffic is allowed. Depending on the path’s moisture content, time of installation, climate and depth of installation, curing times vary.

Creating Accessible Pathways for All

Make your outdoor pathways accessible to all with Kafka Granite. Our experienced team of experts is here to help ensure that every visitor will be able to thoroughly enjoy your next outdoor pathway project. Our stabilized pathway mixes are perfect for both green spaces and commercial locations alike. Let us help you make your next pathway project accessible to all. Contact us today for more information on creating accessible pathways with high-quality mixes.

Every year we help hundreds of clients create stunning outdoor spaces. From ballparks to city parks, we want everyone to be able to enjoy the areas that we assist in creating, that’s why offering commercial wheelchair accessible materials is so important to us.

Providing accessible pathways is a federally mandated priority for all designers and architects. In 2010, the Department of Justice published revised regulations for Titles II and III of the Americans with Disabilities Act (ADA) of 1990. These regulations set minimum requirements for newly designed and constructed State and local government facilities, public accommodations and commercial facilities.